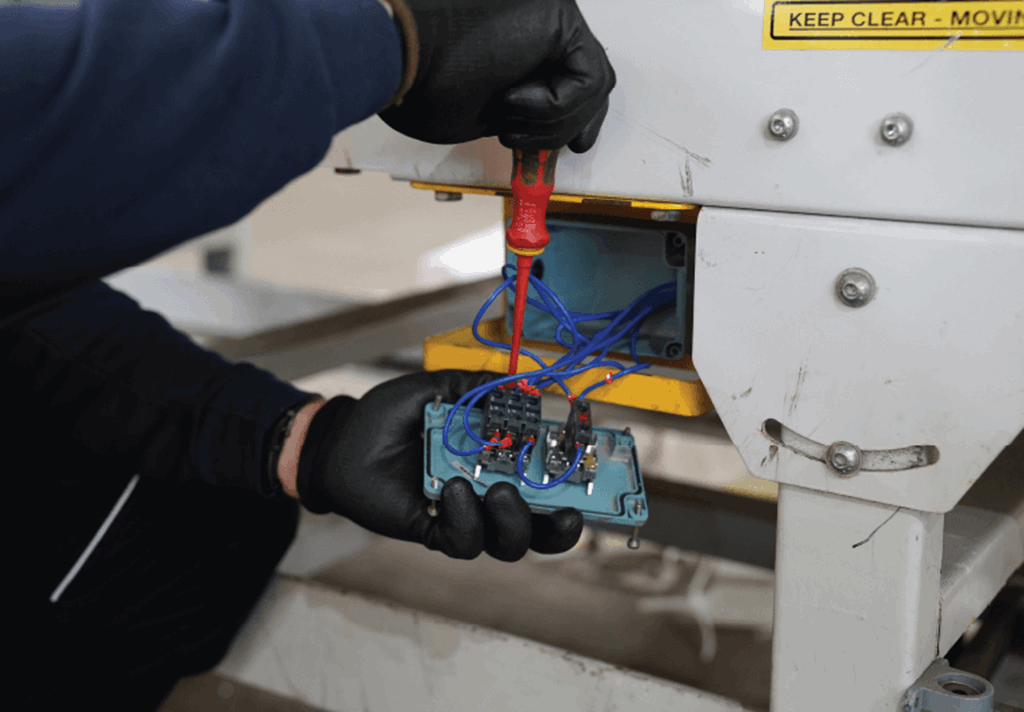

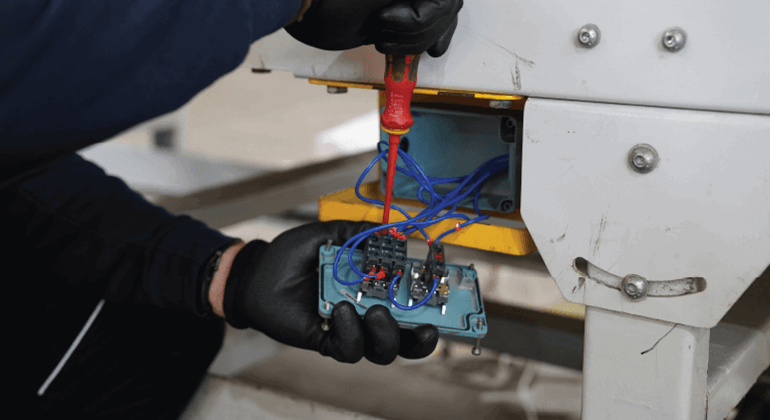

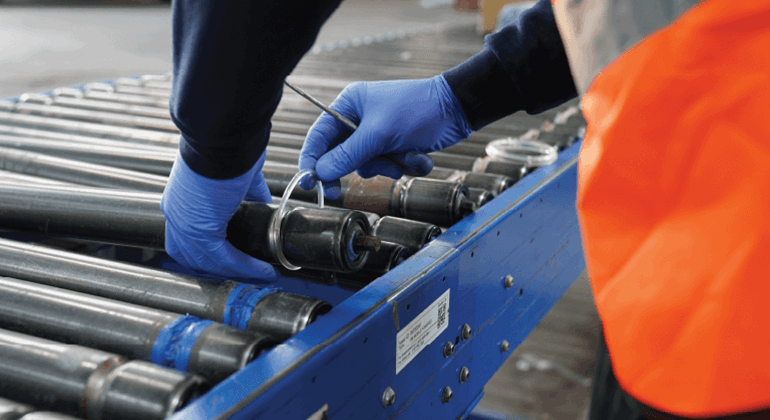

In busy industrial environments, conveyor systems must operate smoothly and as intended to keep the business functioning as usual. Conveyor maintenance goes a long way to ensure the entire system functions as expected and prevents severe problems while maintaining productivity and saving time and money. While proper care of a system reduces the number of times you need to replace conveyor parts, you will need to look at replacement spare parts eventually.

Conveyor systems incorporate mechanical components and moving parts that naturally deteriorate over time with frequent use. Even high-quality systems suffer from wear and tear. When the time has come for a replacement, you should replace conveyor belt parts to maintain optimal functionality and avoid potential damage to the entire system.