The UK agri-food industry is an economic behemoth. Every year, the British spend over £250 billion on food and beverages. The sector - split between agriculture, manufacturing, wholesale, retail, and catering - employs more than four million people, representing about 13% of the country's workforce. Many professionals and machines support this gigantic industry.

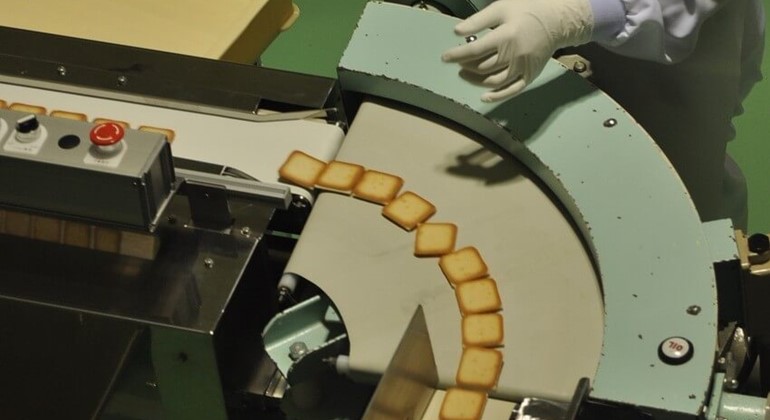

Among these pieces of equipment, one stands out for operating behind the scenes, away from the eyes of the general public: conveyors for the food industry. Find out how conveyors streamline the food chain, transporting infinite goods from farms to customers.