In the logistics industry, what makes the difference between success and failure is efficiency. However, achieving this goal can be pretty challenging for warehouse managers. The relentless increase in competition, the pressure for shorter delivery times, and ever-rising costs can be detrimental. In this scenario, less experienced managers might even think that increasing efficiency is merely a utopia. But, as you will see below, it is indeed possible to make your company more productive without sacrificing business profitability.

tips for identifying and eliminating bottlenecks

Various strategies can be adopted to increase the efficiency and productivity of warehouses. Among them, layout and design audits, cross-training, automation, and maintenance stand out.

layout and design audit

By carefully analysing and reconfiguring your warehouse setup, you can significantly enhance productivity and operational efficiency. Start by mapping the current layout, including storage areas, workstations, loading docks, and pathways. Assess how effectively the available space is being used and identify areas of congestion and underutilised space. Observe the movement of goods, equipment, and personnel to pinpoint inefficiencies and bottlenecks.

warehouse optimisation

To accomplish warehouse optimisation you shoulder consider utilising vertical space by installing taller racks and shelving units. Adjust aisle widths to balance between maximising storage space and allowing efficient movement of forklifts and other equipment. Consider employing high-density storage solutions like pallet racking systems, drive-in racks, and mezzanine floors to increase storage capacity.

Designate clear, unobstructed pathways for the movement of forklifts, pallet jacks, and other vehicles. Optimise the layout of loading docks and staging areas to facilitate quick and efficient loading and unloading of goods. Position frequently used equipment and tools within easy reach of workstations to minimise downtime.

Install pallet racking systems that suit your inventory needs, such as selective racking for easy access or drive-in racking for high-density storage. If your warehouse handles small objects, invest in sturdy, easily accessible adjustable shelving. For long or bulky items, consider cantilever racks.

Create designated zones for different product categories or SKUs, making it easier to locate and retrieve items. Moreover, organise different areas for different operations, such as receiving, picking, packing, and shipping, to streamline processes and reduce cross-traffic. If storing temperature-sensitive items, establish zones with appropriate climate control.

Consider Cross-training

Implementing a cross-training programme ensures that employees are proficient in various tasks, fostering flexibility in workforce allocation and mitigating issues related to absences due to sickness or annual leave.

Cross-training involves systematically training employees to perform multiple roles beyond their primary responsibilities. When employees are given opportunities to learn new skills and take on varied tasks, it can reduce monotony and increase their sense of value within the organisation.

Develop a structured training plan that includes hands-on training, shadowing experienced employees, and regular assessments to ensure proficiency. It's important to create a rotation schedule that allows employees to gain experience in different roles without disrupting the workflow.

Automate the Warehouse

In this regard, we need to be clear: there is no increase in efficiency without automation. Conveyors, guided vehicles, and robotic systems can dramatically reduce human errors, minimise labour shortages, and speed up processing times.

For instance, our conveyor systems, designed by Lodamaster, can transport goods quickly and efficiently across different areas of the warehouse, reducing the need for manual handling and decreasing the risk of damage or loss.

Guided vehicles, such as Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs), can navigate complex environments, transport heavy loads, and operate around the clock without the need for breaks, thereby significantly reducing labour dependency and mitigating the impact of workforce shortages.

These systems can be integrated with advanced software to optimise picking routes, ensure precise inventory management, and adapt to varying levels of demand.

Identify areas where automation can have the most significant impact and choose solutions that align with your operational goals. Contact Joloda Conveyor Services to ensure that the selected technologies are perfectly integrated into your existing systems and processes.

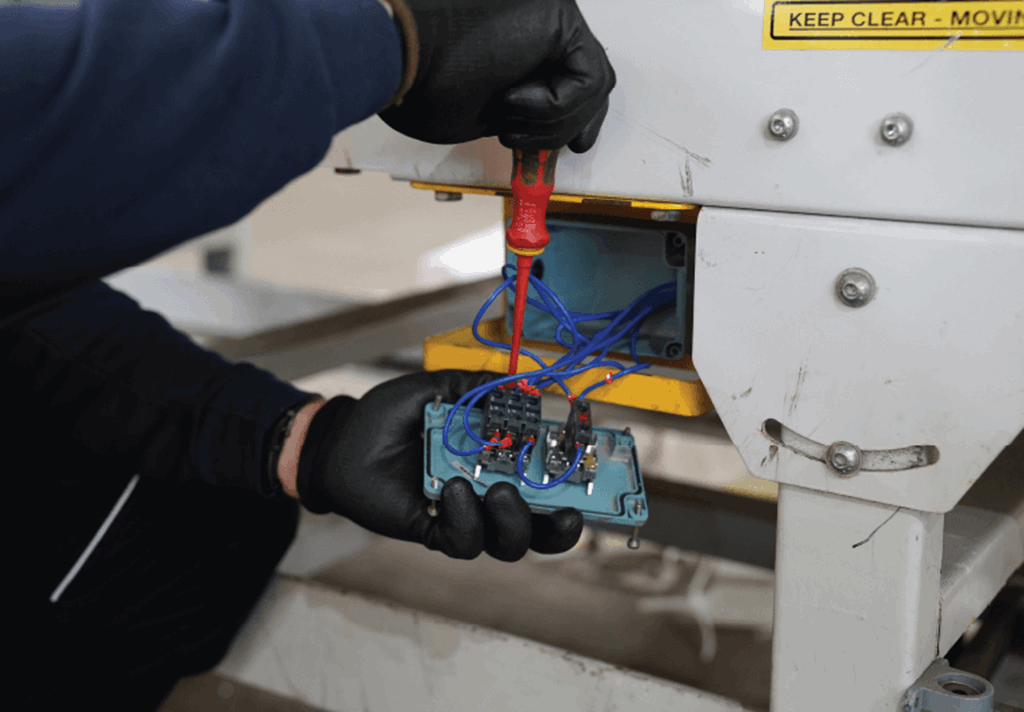

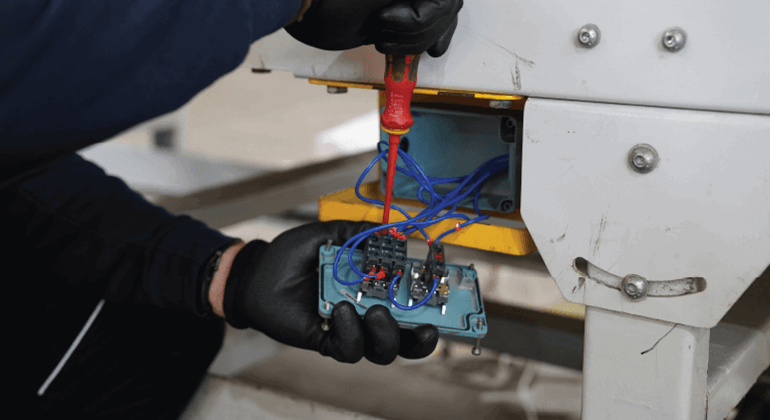

Inspect and Maintain your Equipment

We can't say this enough: Regular equipment maintenance plays a pivotal role in sustaining productivity. By implementing a systematic maintenance schedule, you can ensure that all equipment, including forklifts, conveyors, automated systems, and other machinery, operates smoothly and reliably. Well-maintained machinery operates more efficiently, leading to faster processing times, reduced energy consumption, and lower operational costs.

To establish an effective maintenance programme, start by creating a comprehensive inventory of all equipment and machinery in your warehouse. Develop a maintenance schedule that outlines specific tasks, inspection intervals, and responsible personnel. This schedule should include routine checks, cleaning, lubrication, part replacements, and any necessary repairs.

Joloda Conveyor Services offers a range of solutions to help your equipment perform at its peak. We specialise in conveyor repair breakdown service, pre-planned conveyor maintenance, and conveyor asset management. Our call centre is available 24/7, and our team can reach anywhere in the UK in record time.

how to measure warehouse efficiency

To ensure a warehouse operates at peak efficiency, it is crucial to regularly measure and evaluate its performance. The best way to do this is by using Key Performance Indicators (KPIs). The KPIs you must follow are:

- Order Picking Accuracy: Measures the percentage of orders correctly picked and fulfilled without errors.

- Inventory Turnover: The rate at which inventory is sold and replaced over a specific period.

- Order Cycle Time: Estimates the total time taken from receiving an order to shipping it out.

- Warehouse Utilisation: Assesses how effectively the available storage space is being used.

- Labour Productivity: Measures the output per worker, typically in terms of units picked, packed, or shipped per hour.

- Rate of Return: The percentage of shipped orders that are returned by customers.

- Dock-to-stock Time: Calculates the time taken to move goods from the receiving dock to their designated storage locations.

- Cost Per Order: Determines the average cost incurred to process an order, including labour, packaging, and shipping expenses.

With an integrated approach that combines advanced technology and a well-trained team, companies can significantly improve efficiency, reduce operational costs, and increase customer satisfaction. Partnerships with specialised companies, like Joloda Conveyor Services, offer innovative solutions that help transform warehouse operations, ensuring optimised and sustainable performance.

maintain your conveyors with joloda conveyor services

Our maintenance service keeps your conveyor system running efficiently and safely. Our engineers will assess your machine and advise whether you need conveyor service, parts replacement or other essential work. We'll flag any areas of concern and the work required to prevent future problems. Our team will also check if there's anything more immediate that you need to address regarding conveyor safety.

Regularly maintaining your conveyor system prevents accidents caused by malfunctions or faulty operations. Contact us today to learn more about our services.

about joloda conveyor services

We are a unique service provider, focused 100% on repairs, maintenance and refurbishment of conveyor systems. Our team of conveyor carers are experts because they are not distracted by lots of additional bolt-on services; when your equipment needs attention, we’ll carry out conveyor troubleshooting and fix the problem to get you back operational as quickly as possible.

Learn more About Us and how we can help to keep your, and the nation's conveyors rolling, by preventing and fixing common conveyor belt problems.

About Us

we're trusted...