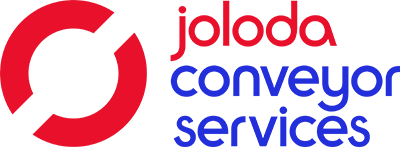

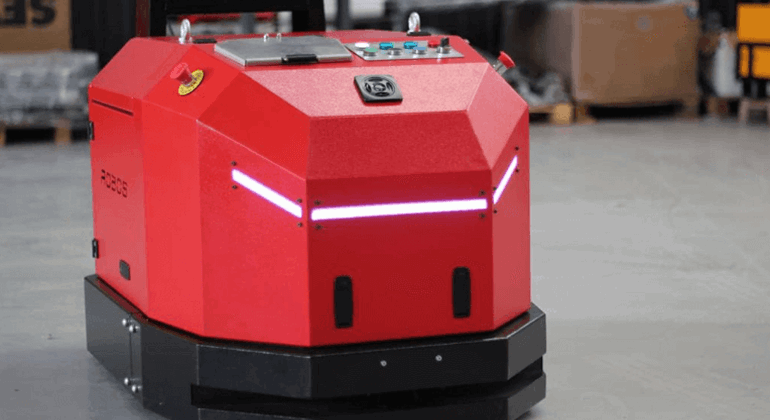

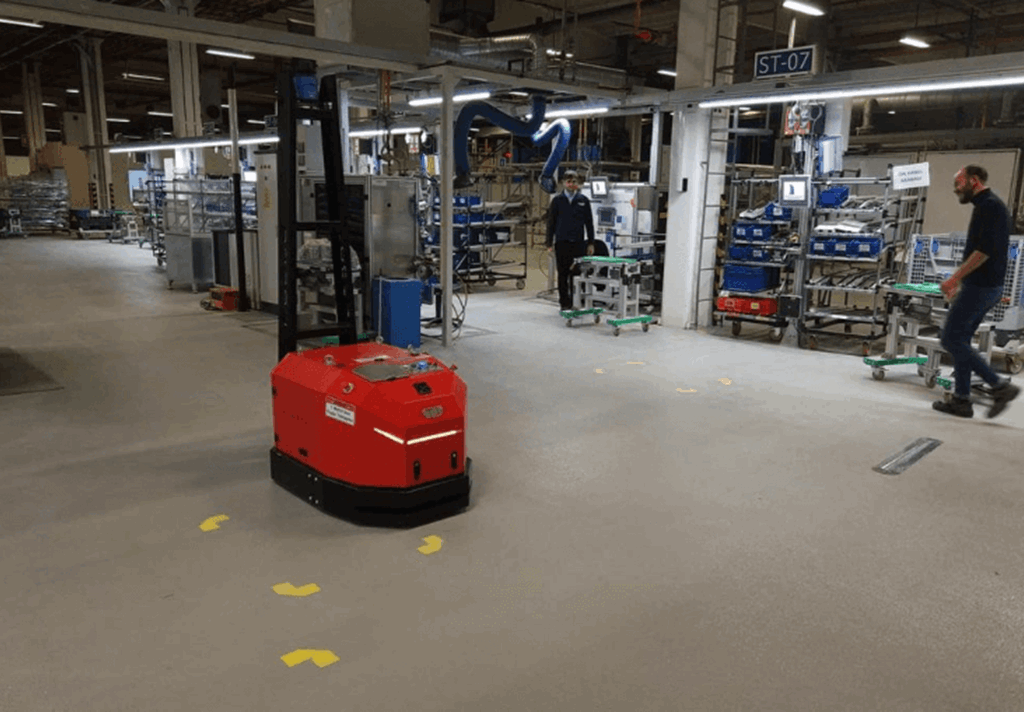

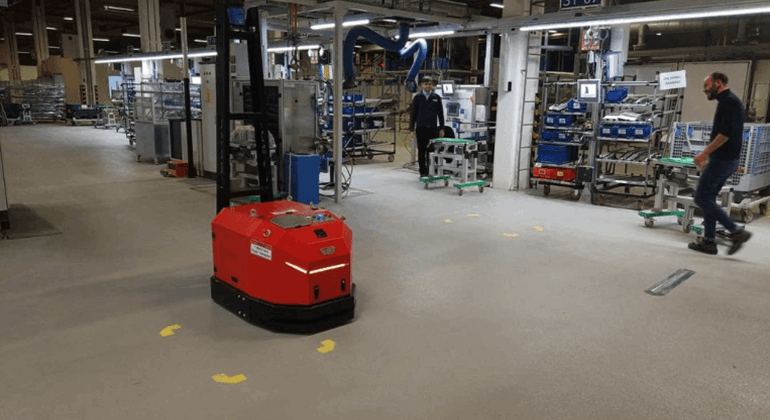

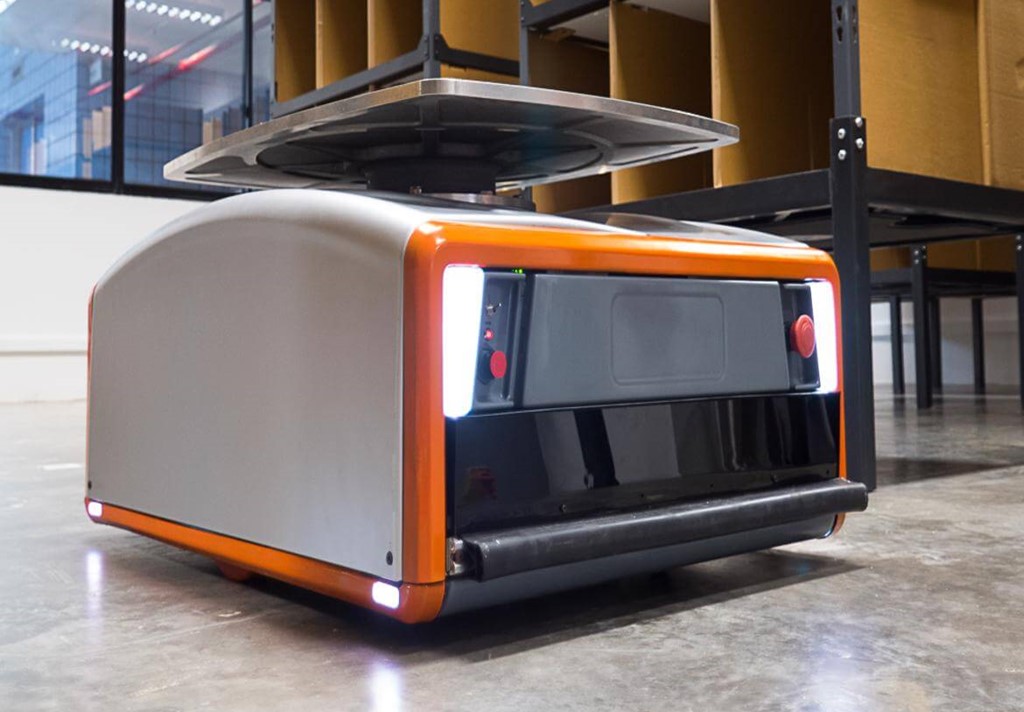

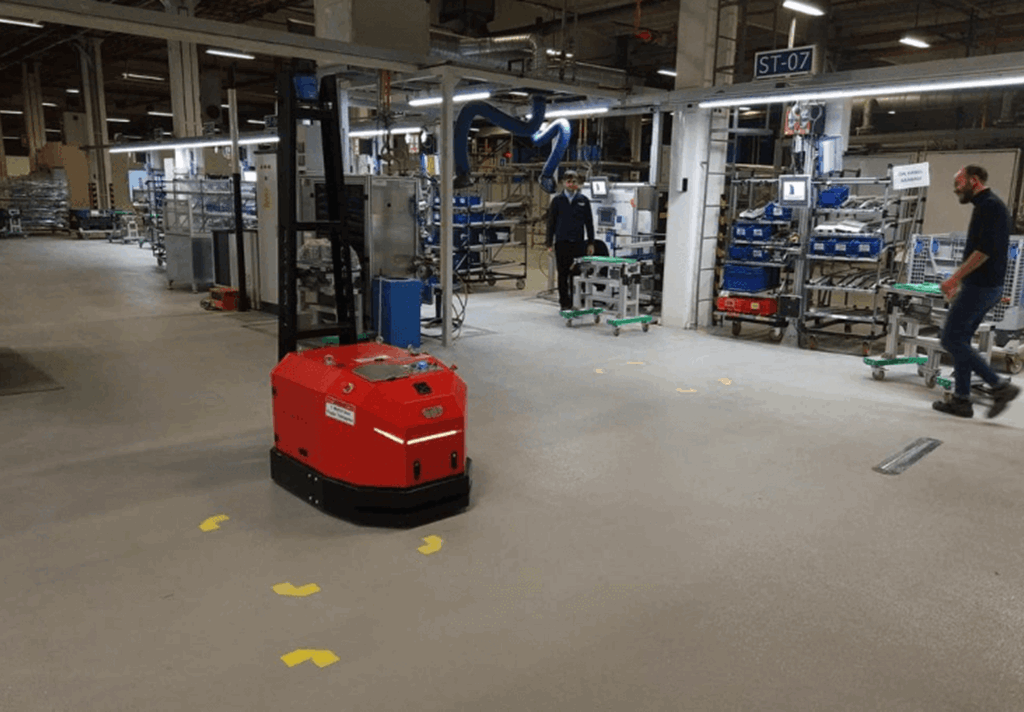

Order consolidation is crucial for companies looking to streamline operations and reduce costs. At Joloda Conveyor Services, we offer a range of reliable and durable order consolidation products, including autonomous mobile robots, mini-sorting robots and pick/put to light systems.

These products are designed to automate order consolidation and improve operations speed and accuracy. Our systems are built with reliability and durability in mind, ensuring they can handle your business demands. With our advanced technology, you can be confident that your orders will be consolidated quickly and accurately without errors or delays.

book a free conveyor assessment

We'll visit you to perform a thorough conveyor assessment and identify opportunities to improve your logistics processes.

Get in touch