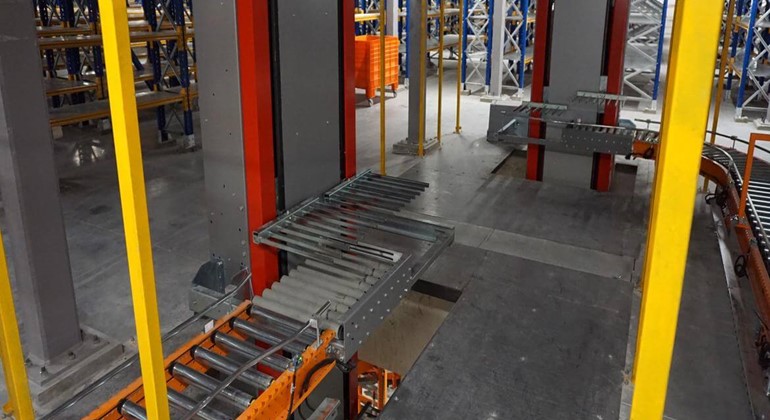

In the manufacturing industry, vertical conveyors can be used to transport raw materials, such as metals, plastics, and textiles, to the production line. They can also move finished products, such as electronics, appliances and automotive parts, from the production line to storage or shipping areas.

In the food and beverage industry, vertical conveyors can transport packaged goods, such as cans, bottles, and boxes, to packaging machines or storage rooms. They can also transport bulk materials, such as grains, flour and sugar, from storage areas to processing machines.

Vertical conveyors can be used in various industries, including automotive, aerospace, electronics, food and beverage, pharmaceuticals, and more. Any industry that requires the movement of materials vertically can benefit from using a vertical conveyor.

The materials that can be moved depend on the specific model and design of the conveyor. They can handle heavy loads and are designed to accommodate a wide range of shapes and sizes. Vertical conveyors can also be customised to address specific materials, such as fragile or hazardous items.