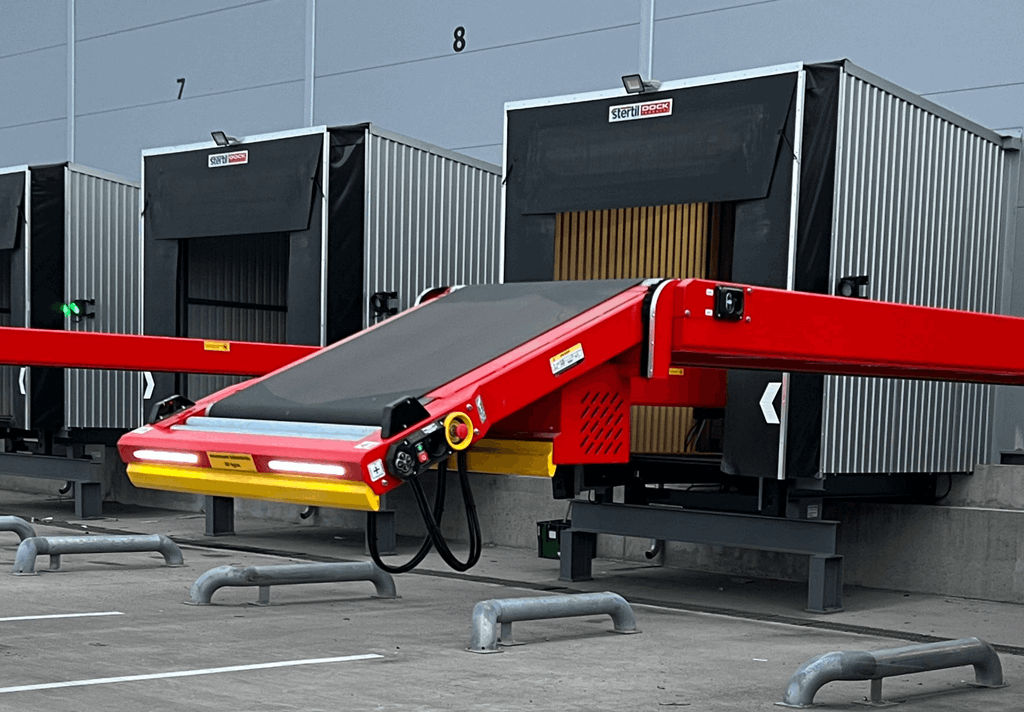

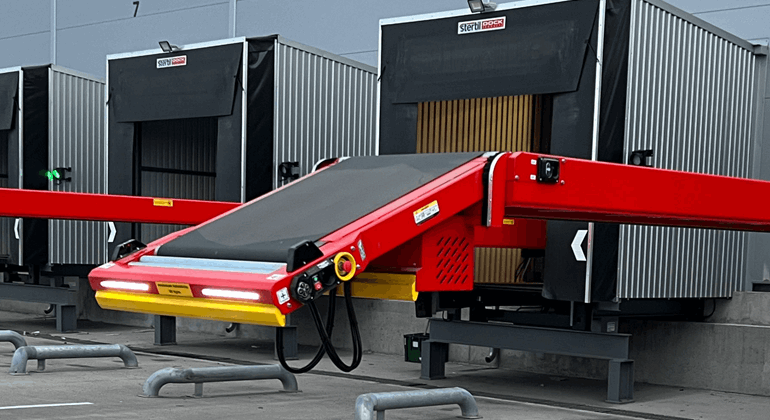

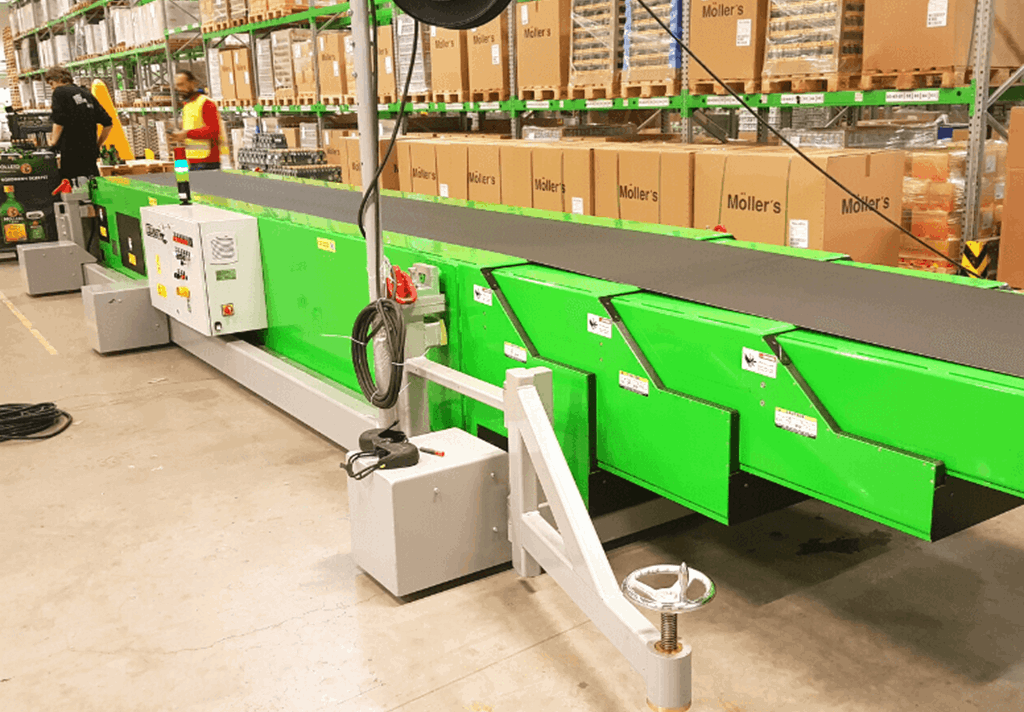

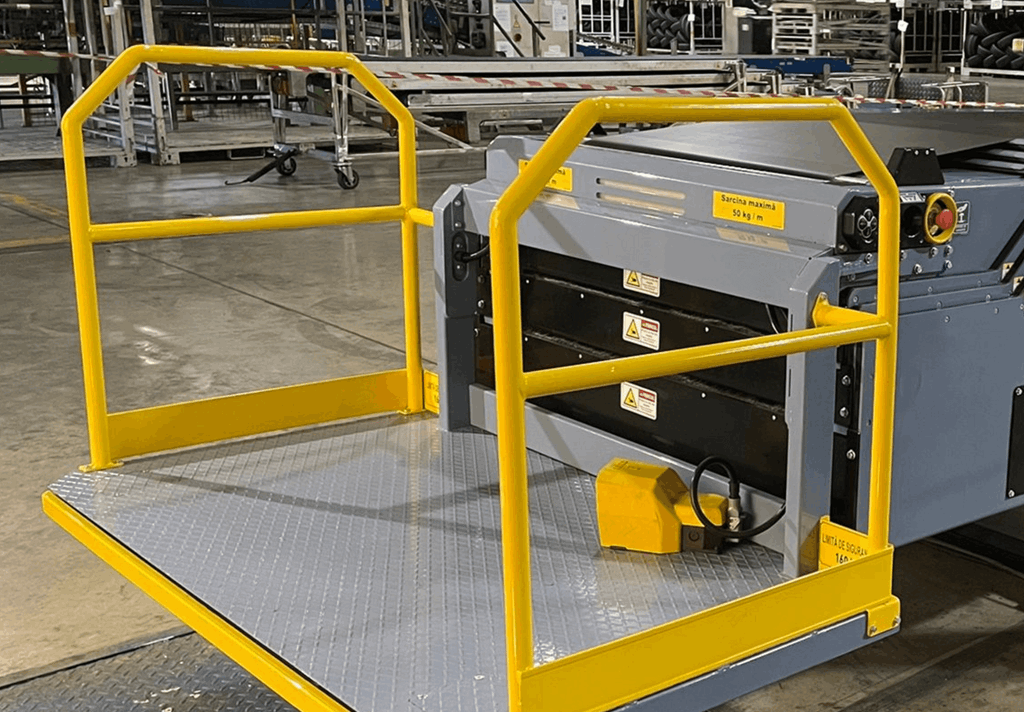

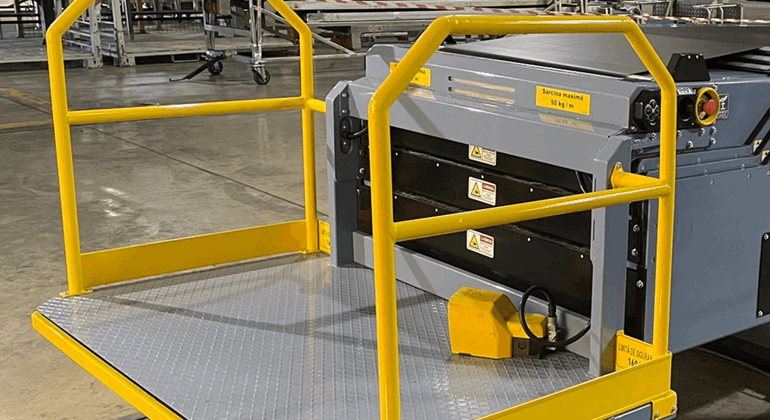

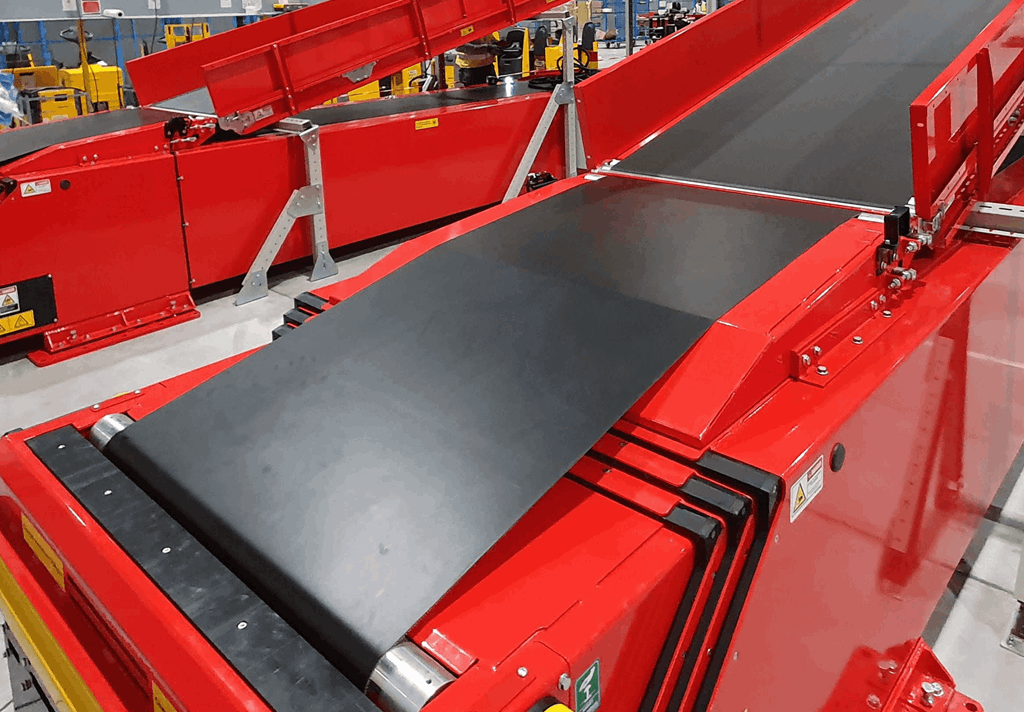

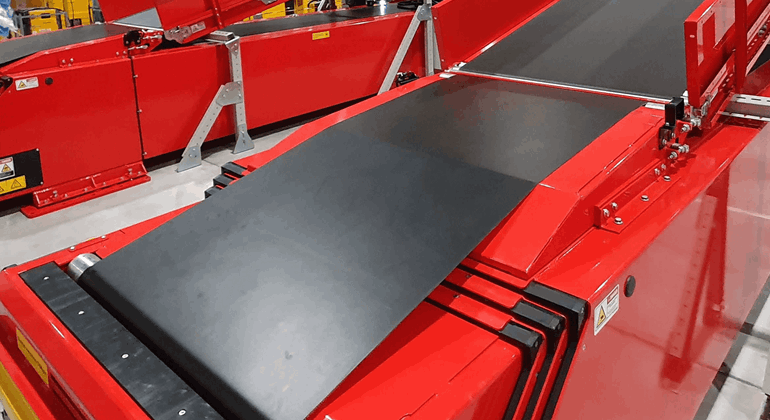

Joloda Conveyor Services offers several optional features for the telescopic conveyor, including:

book a free conveyor assessment

We'll visit you to perform a thorough conveyor assessment and identify opportunities to improve your logistics processes.

Get in touch